Moblie: 8613816755915

Panelized Home

What is the Prefabricated panelized Home

Prefabricated panelized home system is a high-performance fabricated homes system for residential and light commercial buildings. The traditional panel consists of two structural panels (usually OSB) ,The Solidhome has improved the traditional prefabricated panelized home system, giving it more powerful load-bearing capacity and plasticity, replacing the original wooden edge with a more durable lightweight steel edge. The European pine board is replaced by a more mildew proof and waterproof magnesium oxychloride board / glass magnesium board. The insulation foam core is still used in the middle, and a new plate type quick assembly system is formed. Panels are manufactured under factory controlled conditions and are suitable for almost any architectural .

Advantages of the Prefabricated panelized Home system

The panelized home system offers a number of advantages over traditional construction methods, making it an attractive option for those who want to build a beautiful and energy-efficient home quickly and efficiently.

Easy Installation

The most obvious advantage of the panelized home system is that it is much faster than other construction methods. Because the panelized home kits are already pre-fabricated and designed to fit together quickly and easily, the building process can be completed in a fraction of the time it would take to build a home using traditional methods. This makes it an ideal option for those who are looking to build a home quickly and cost-effectively.

Energy efficient

Another advantage of the panelized home system is that it is much more energy efficient than traditional construction methods. The panels used in the construction process are designed to be airtight, meaning that they can help to reduce energy costs by preventing air leaks and improving air quality. In addition, the panels also provide excellent insulation, which can help to reduce energy costs even further.

Aesthetic advantage

Panelized home systems also offer many aesthetic advantages over other prefab homes. The panels are exquisitely designed and stylish, and can be customized according to your own personal style, while other prefabricated houses cannot achieve the effect of panelized home system cornices due to the limitation of fixed dimensions . The panels can be designed to match the design and color of an existing home, blending the two seamlessly.

Strong structure

Panelized home systems are designed to be strong and durable. These panels consist of Rigid foam core with two layers of structural board, have superior structural performance to wood framed and steel framed walls . Under extreme conditions such as earthquake and wind protection, the seismic performance of the panel is better than other buildings. The panelized home kits lasts longer than other fabricated homes, at least guaranteed to last at least 70 years.

Assembly of panelized home kits

The installation sequence of panelized home kits is like this: bottom frame — wall panel — roof — garage.

1. Install the floor frame of the floor. After the floor supports positioning, use the horizontal meter to measure the horizontal point.

2. Install the fixed bolt on the wall panel, the bolt cover is covered on the fixed bolt, and the wall panel is slowly and parallel, until the wall panel is completely exposed to the floor. While the lock bolt is tightened, ensure that the wall surface is maintained vertically, which is convenient for subsequent wall panel installation.

3. Put the wall panel in order, and adjust the installation angle at the same time to ensure the vertical state of each wall panel until all wall panel are installed.

4. Install the roof Lugs and hang it parallel. When the roof drops to 100 m, wear a wire.

5. After wearing a wire, slow down the roof and fit the wall panel.

6, parallel hanging garage, put the pillar feet at the pillar pillar connection in turn. After installing it in turn, it drops to the ground contact.

7. Finally, the houses around the house are installed.

Elements of prefabricated panelized home quick installation system:

- Patented fixing system, fast assembly mode, reducing labor costs

a. Wall: quick connection system between wall panels

b. Floor: adjustable height multi-platform floor system

c. Roof: large format quick connection system - Use large size panels

a. Glass magnesium board with GPS core

b. Dimensions: length 12 m, height 3.5 m

c. Wall: 120 mm exterior wall, 120 mm interior wall

Prefabricated panelized home system – Strength:

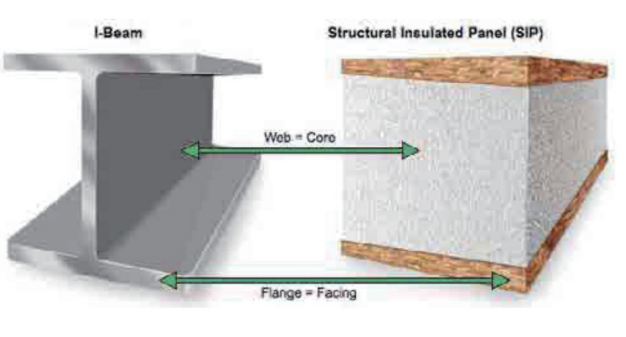

1、Rigid foam core with two layers of structural board

2、MGO panels have superior structural performance to wood framed and steel framed walls (up to 2X)

3、Share the same structural properties as L-Beams and I-Beams

4、Under extreme conditions such as earthquake and wind protection, the seismic performance of the panel is better than that of other buildings.

Prefabricated panelized home system – Sound insulation:

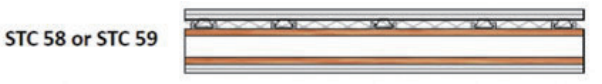

Two rows of 50×100 mm wooden keels are staggered between traditional walls, and sound-absorbing material (STC 55) is placed on one side. Solidhome prefabricated panelized home kits can reach (stc 58-59). The prefabricated panel has continuous insulation and fewer gaps to be sealed than traditional wood structure and light steel structure walls, so the sound propagates less through the gaps in the wall components.

The core of each component is a standard precast panel consisting of an insulating foam core (GPS) and two sides of the magnesium oxysulphide (MGO) skin. Directly connected to one side of the panel is 12 mm X-type gypsum wallboard. On the other side, a clip is screwed to the panel. Then clip the cap groove into the clip and fix 12 mm X-shaped plaster on the cap groove. The clip minimizes the contact area of each layer of the assembly, which helps to separate the assembly and reduce sound transmission, while providing sound insulation quality for the entire assembly. Additional sound insulation can be achieved by adding 60 mm glass fiber insulation to the space between the panel and gypsum generated by the clip. The components are non directional, so the clip system can be installed on either side of the wall preferred by the architect.

Advantages of Prefabricated panelized home kits system include:

1、Allows for highly efficient CAM manufacturing process

2、Rapid on-site installation

3、Improved building quality

4、Design flexibility

5、Superior structural performance with rigid building structures

6、High fire-ratings

7、Environmentally sustainable

8、Earthquake resistance and wind protection

9、Excellent thermal properties – 70% more energy efficient than conventional concrete and wooden

Prefabricated panelized home system –Fire Ratings:

- Solidhome customized MGO meets all fire rating single storey and low rise residential units in Australia, Europe, Japan and North America.

- Most 12 mm MGO board has a two-hour fire rating.

- MGO board does not burn, and is a poor conductor of heat.

- MGO does not produce toxic off-gassing when burned at temperatures greater than 700 degrees.

- MGO is stronger than plywood, OSB, and particleboard. It doesn’toff-gas VOCs like OSB’s formaldehyde-laden glue.

- MGO has superior fire suppression characteristics when compared to portland cement, OSB, and plywood.

- MGO’s water-resistant characteristics make it more resistant to mould than plywood, OSB, and gypsum board

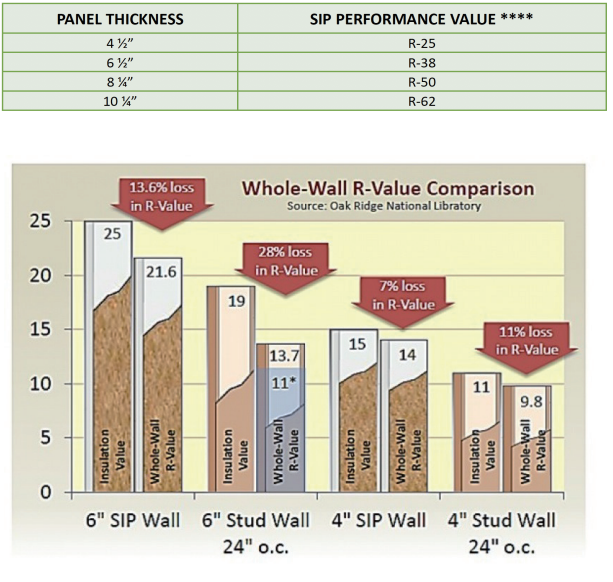

Prefabricated panelized home system -Thermal Performance

Insulation is one of the key components of any energy-saving residential or commercial building. Insulation is evaluated by R value and the thermal resistance of materials is measured. Insulating materials with higher R value form a more effective thermal barrier between outdoor temperature and indoor air-conditioned space. As shown in the figure, Solidhome prefabricated wall panels provide more R values than wooden dragon bone walls or light steel walls of the same thickness.

- Very high R values and very low thermal bridges minimize heat transfer between the internal and external surfaces of the building

- In closed buildings, the energy consumption is low and the thermal efficiency is as high as 95%

- Low carbon emission green building technology

- When considering real-world factors such as thermal bridges and spray foam (PU) and glass fiber installation gaps, precast wallboard can provide continuous insulation, maintain its prescribed R value, and be better than glass fiber insulation.

- When the wood keel or steel structure in the structure transfers heat from the interior of the building to the outer surface, a thermal bridge will occur, but there is only a small amount of steel structure in the prefabricated plate quick assembly panel. Therefore, the generation of thermal bridge phenomenon is far lower than that of traditional structures

Based on Test Results: Whole Wall Rating Label for Structural Panel: Steady-State Thermal Analysis. June 4, 1999, OakRidge National Laboratory. Also refer to Federal Trade Commission 16 CFR Part 460, labeling of home insulation.

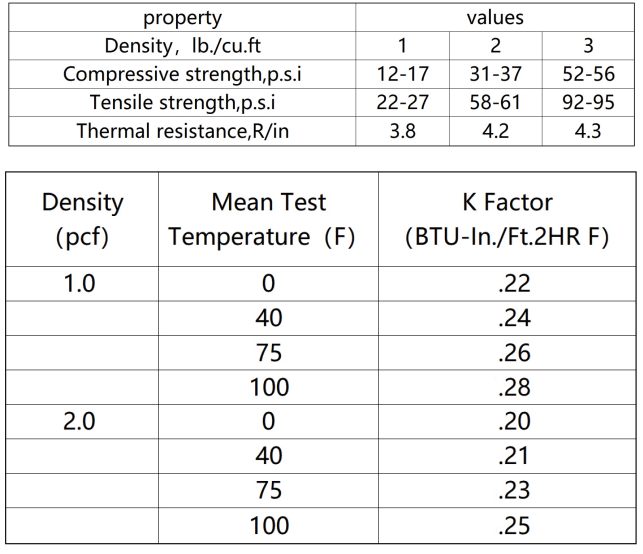

Excellent Insulation Value

GPS has strong resistance to heat flow. Its uniform and closed honeycomb structure limits radiation, convection and conduction heat transfer.

Significant Cost Savings

GPS material prices are highly competitive in the market. The versatility and light weight of the material itself make it more economical in design and development, product assembly and distribution costs.

Water Absorption And Moisture Permeability

The porous structure of polystyrene is basically impermeable and provides zero capillary.

Chemical Resistance

Aqueous solutions of water and salts, acids and bases do not affect molded polystyrene, and most organic solvents are incompatible with GPS