Moblie: 8613816755915

Modular home vs. SIP construction, which prefab home is better

Both forms are heavily utilized in the prefab home family, and how do you, as a homeowner, come to choose? We analyze both forms of prefab home step by step.

The two structural forms: modular home and SIP construction.

Modular home

Definition

Prefabrication of standardized modules (e.g., rooms, wall units, etc.) in a factory, transported to the site and assembled into a complete building.

Advantages

Fast construction speed Factory prefabrication parallels on-site construction, reducing weather impact and shortening construction period by 30%-50%.

High quality control Standardized production in a factory environment reduces human error and reduces material waste to 10-20% of traditional construction.

Environmentally sustainable Precise material cutting reduces waste and module home can be disassembled and reused.

Predictable Costs Factory production facilitates budget control and reduces labor costs by 20%-30%.

Disadvantages

Low design flexibility Module sizes are limited by transportation (e.g., road widths), and standardized designs may sacrifice individuality, resulting in a scarcity of modular home models.

High connection technology requirements Structural connections between modules need to be precisely designed to address waterproofing/soundproofing issues depending on the situation.

Typical applications

Student housing, hotels, medical facilities, post-disaster emergency buildings.

SIP construction

Definition

A standard SIP consists of two oriented strand board (OSB) interlayers (“bread”) and expanded polystyrene (EPS) or polyurethane insulation to form the “meat” of the interlayer that completes the structural wall system. Solidhome’s panelized home is a SIP building.

Advantages

Energy efficient Depending on the thickness of the insulation and the choice of EPS or polyurethane, SIP construction is 2-3 times more energy efficient than traditional walls, reducing heating/cooling energy consumption by 40-60%.

High structural strength SIP construction structurally strong because they can form some sort of continuous beam. Think of a wide-rimmed steel beam or an I-beam, often called an I-beam because their cross-section looks like a capital “I.” The OSB jacket acts as the flange, and the insulation becomes the web or vertical portion of the I-beam. One-piece design with load-bearing capacity better than wood structure, suitable for low-rise buildings.

Excellent airtightness With fewer seams and more airtight materials, the SIP structure has an air infiltration rate that is only 10% of that of conventional buildings, improving energy efficiency.

Disadvantages

Higher cost SIP construction is mostly owner-occupied, material requirements and renovation costs are 10-20% higher than wood structures, mostly personalized designs, and large investments in mass production equipment.

Design relies on prefabrication Requires precise design in the early stage, longer design cycle, difficult to modify in the later stage.

Typical applications

Energy efficient homes, small commercial buildings, roof retrofits, passive houses.

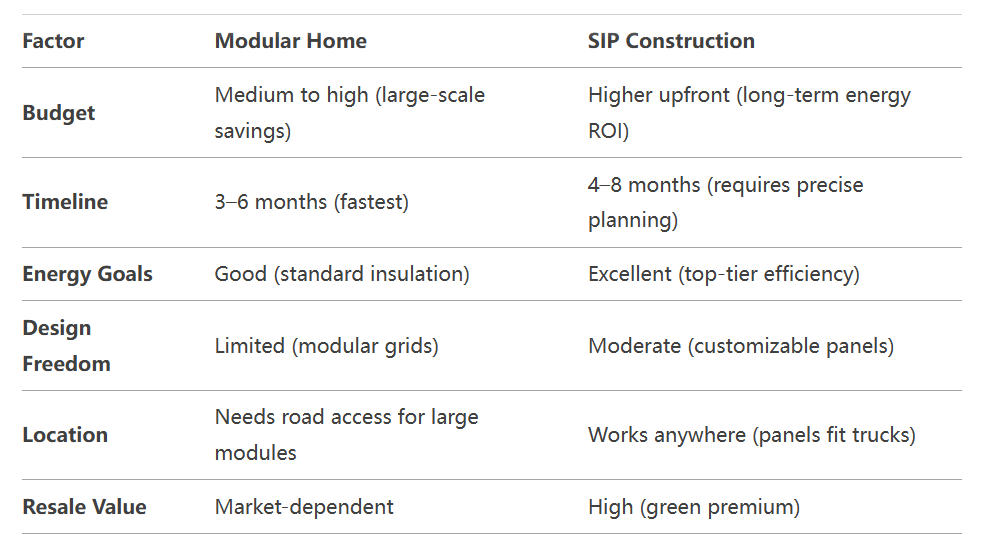

Comparison of the two forms and suggestions for selection

Final conclusion

- Modular home win for speed, scalability, and urban/suburban projects.

- SIP construction wins for energy savings, durability, and custom low-rise homes.

Pro Tip: If budget allows, explore hybrid SIP modular designs—they’re the future of prefab!